Contents

If you have been running a print on demand clothing business, you probably have heard about the term sublimation and screen printing. They’re both popular printing techniques for clothing, but serve different purposes and have different performance. In this post, we’ll help you clarify the differences between sublimation vs screen printing, how they work and help you decide the most suitable one for your business.

Right on, let’s get to it!

What is sublimation printing and how does it work

Sublimation printing (also known as dye sublimation) is the printing process that uses heat and pressure to transfer the design from sublimation paper directly into the fabric. This technique works best for all-over print products, such as clothing, flag, doormat, tire cover, tote bags, pillow cover, and so on.

In this process, you put the sublimation paper with the design on top of the shirt or other material, clamp it tight in the heat press, crank up the temp, wait for the design to sublimate and fuse with the fabric. The pressure also presses it in deep, instead of just laying ink on top. This process results in a permanent imprint that is vibrant, high-quality and can last through tons of wear and washes without fading or cracking.

Here is a step by step process of how sublimation puts the ink to the fabric:

- You print your slick design onto special transfer paper with a dye-sub printer filled with colorful sublimation inks.

- Lay the sublimation paper on top of a shirt or other material. Then place them together in a heat press and crank that sucker up to scorching temps while clamping down hard.

- Now here’s where the magic happens! That extreme heat turns the inks into a gas that seeps into the fabric. The pressure from the heat press squishes it in deep too.

- And just like that, after the shirt cools off, your design is now perfectly melted into the fibers! So it’s not sitting on top like a normal print – it becomes part of the shirt. That’s why the colors pop so nice and vivid-like, and they’ll never crack or peel.

You can take a look at how the sublimation process works at Merchize factory.

What is screen printing and how does it work

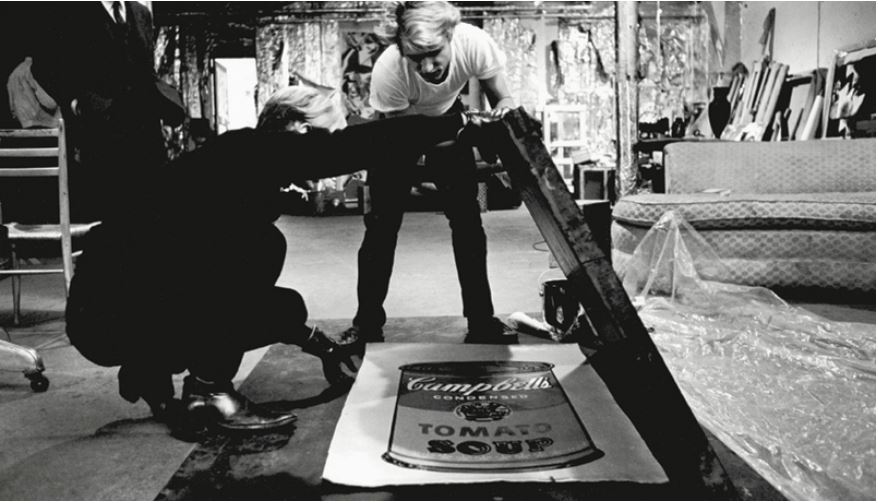

Screen printing has been around forever – we’re talking thousands of years! It started as a way to add designs to silk. The basic idea is you make a stencil on a fine mesh screen, then use a squeegee to push ink through the open parts of the stencil. The ink prints the design onto the shirt or fabric underneath. It’s an old-school technique but started booming in more modern times when artists like Andy Warhol invented the coolest printed shirts in the 1960s.

The process today works much the same but with better tools. For multi-colored prints, you need a separate stencil screen for each color. The printer layers them one by one. Of course more complex designs take more time as each color needs to dry first. The inks sit on top of the material instead of bonding inside it too. This is different from sublimation which injects ink into the fibers. But screen printing has the advantage of working on all types of fabrics using some seriously bold, vibrant inks!

Here’s how to create POD products using screen printing:

- Print the design on a see-through acetate film. Then, pick a mesh screen that fits the fabric and the design’s complexity.

- Put a special light-sensitive coating on the mesh. After that, place the film on the mesh and shine a bright light on it. The light makes the coating hard where there’s no design. Get rid of the extra liquid, and it leaves a kind of outline on the mesh screen, like a stencil.

- Put the screen on a printing machine over the fabric, then lower it down to touch the fabric for the inking part. The ink is pressed through the mesh outline, printing the design on the fabric. Do this for each piece of fabric, let it dry, and check to make sure it looks just right.

This video helps you better visualize the process of screen printing.

Comparison between sublimation vs screen printing

Finding the most suitable printing method is an important issue to consider when running a print on demand clothing business. In this section, we’ll dive into the differences between sublimation vs screen printing and explain the pros and cons of each.

1. Print quality

When it comes to print quality, screen printing nails it with vibrant, eye-catching colors and bold designs. It works best for logos, texts and simple graphics. But printing complex multi-color images like photos can be tricky with all those separate stencil layers.

Sublimation also churns out some gorgeous prints though, with colors just as sharp and vivid. Plus it can easily handle detailed designs or photographs with lots of different hues since there’s no color separation. The ink just flows freely into the fabric.

So if you just need to spotlight text or simple logos, the classic screen printing never goes wrong. On the other hand, if you have a thing for photo prints, sublimation is the smart move.

2. Durability

In screen printing, the ink just stays on top of the fabric instead of really soaking in. That means the more colors you add, the thicker the layer becomes. The plastisol ink makes the prints decently durable, but after a bunch of spins in the washing machine, it might start cracking or peeling at the edges, and the colors fade a little.

Sublimation prints go the distance though. The ink blends tight with the fabric fibers when it turns to gas and sinks in. So it basically becomes one with the shirt instead of sitting on top. This makes the colors stay bold and beautiful wash after wash – no fading, cracking or peeling!

Now screen printed shirts can still hold up nice if you take care of them. But sublimation definitely wins for long-lasting, durable prints. The colors lock in and don’t budge! So if you prioritize longevity for your merch, sublimation is probably the way to go. Screen printing works great for basic designs though, and gets the job done on a budget!

3. Special effects

Screen printing allows you to incorporate special effects using specialty inks. We’re talking 3D puff designs, neon hues, glow-in-the-dark, shimmers – if you want showstopping prints, the options are wide open! You just have to add each effect as a separate ink layer screened on top.

On the other hand, sublimation offers unique effects with depth and textures, such as metallic, glitter, cracked, or leather effects.

Now one thing sublimation nails is full color images like photos. It only needs the basic CMYK process color inks to replicate a huge range of hues. Screen printing takes more mixing and matching to print complex designs colorfully, especially photographs.

But both give you lots of room for creativity if unique, textured prints with visual impact are your thing! Sublimation fuses the effects into the shirts. Screen printing stacks them on top. So bring some personality into your prints and play around!

4. Design complex

Screen printing wins at simple designs with just a color or two. But things slow down when you print more colors since each one needs its own screen layer. Plus the printer’s mixing and matching all those custom color shades by hand. So you might not get the exact same tones each time – it varies based on who’s doing the blending.

Sublimation is better used for complex multi-color and photographic prints since there’s no color separation. The printer just uses cyan, magenta, yellow, black to create a huge spectrum of colors accurately thanks to handy software profiles. This makes blending precise tones for gradients and photos super consistent.

Screen printing can print on any color shirt at ease since the ink lays on top. But sublimation only shows up well on light fabrics because the inks are transparent and sink into the shirt.

So if simplicity and versatility matters most, screen printing fits the bill. But when color precision and multi-tone designs come into play, sublimation has its number all day!

5. Materials

Screen printing is more suitable for natural fibers, such as cotton or silk, as the ink adheres and holds on decently through washes. And with specialty inks, you can print on all types of materials – polyester, sure – but also paper, wood, metal, plastic.

Conversely, sublimation printing jives well with fabrics that contain a polyester blend, nylon, spandex, lycra – you name it. Cotton can work too, but sublimation makes magic happen on those synthetic performance fabrics. Beyond shirts, sublimation is a good choice for printing photo mugs, phone cases, ceramic tiles, even coasters as the smooth, polymer surfaces grasp the ink beautifully.

6. Environmental impact

Screen printing often relies on plastisol inks which can be harsh on the planet since they contain some toxic chemicals that won’t break down. Ordering shirts in bulk saves money but risks wasted stock if your designs don’t sell out. Not ideal.

However, some screen printers can use water-based inks instead which are more eco-friendly. And smart product planning helps minimize leftover merch that ends up in landfills.

On the other hand, sublimation printing uses less natural resources like water than other decoration methods. The ink itself is non-toxic too. And production aims to recycle fabric scraps, like sewing leftover T-shirt material into funky headbands!

So both methods can take steps to go green. Screen printing just needs some extra care when selecting inks and managing inventory. Sublimation works clean right from the start. Either way, our planet thanks you for prioritizing eco-friendly printing!

7. Quantity required

Sublimation printing can efficiently produce small customized batches or large bulk orders with equal ease. Since the process is highly automated, the printer can accommodate single orders up to hundreds without intensive additional labor. This makes sublimation well-suited for print on demand fulfillment models that print products as orders are received rather than pre-stocking inventory.

Screen printing involves more manual preparation like creating custom stencils. Therefore, most screen printers prefer large bulk orders around 25+ units to maximize workflow efficiency and cost benefits. For the upfront stencil set up and labor time, optimizing high volume runs reduces the overall cost per printed item.

In summary, if your business model requires flexibility to profitably print 1-2 shirts at a time or scale to big numbers quickly based on viral demand, sublimation may be better aligned to that need. But for businesses focused squarely on high volume production runs to fulfill wholesale or branded orders, screen printing provides economies of scale.

8. Price

Screen printing means taking the time to mix inks, make stencils, and manually print each shirt. Not very practical to fire up all that setup for a few shirts. Bulk orders around 25+ makes it worthwhile, lowering the cost per tee. But overordering shirts risks wasted dough and excess stock. So screen printing thrives on high volume runs rather than fast on-demand jobs.

Sublimation is like a custom T-shirt factory on demand! Since heat presses and sublimation printers automate the decorating process, it takes the same effort to make 1 or 100 shirts. No stencils, no mess, no fuss! This flexibility keeps small batch costs reasonable while allowing instant scaling if a design goes viral. And you only order blank shirts as needed so no leftover stock. Perfect for printing exactly what’s ordered exactly when it’s ordered!

If pumping out stacks of shirts is the name of your game, ride that screen printing train all the way to Bulk Discount town! But for low minimums and agile on-demand fulfillment, sublimation is on point!

If you have difficulties remembering all the information above, we’ve got a handy cheat sheet for you! Here’s a side-by-side comparison of what each one’s got.

| Criteria | Sublimation Printing | Screen Printing |

| Print Quality and Durability | High-resolution, photo-realistic prints

Durable, long-lasting Embedded into fabric fibers |

Excellent print quality

Durable, vibrant colors May fade over time |

| Performance / Color and Finish (Special Effects) | Limited to all-over prints

No texture or raised effects; Difficult to achieve special effects |

Versatile for various textures and finishes

Can achieve specialty inks and effects |

| Color Diversity | Unlimited color options

Full-color spectrum |

Limited color options

Spot color printing |

| Design Complexity | Ideal for complex and intricate designs

Gradient effects |

Suitable for simpler designs

Limited gradient capabilities |

| Customization | Full customization

Individualized prints on each item |

Limited customization

Set-up required for each color |

| Fabric and Materials | Best suited for polyester fabrics, limited to light colors | Works on various fabrics, including dark colors |

| Environmental Impact | Low waste as inks are absorbed

Minimal use of water |

More waste in screen preparation

Requires more chemicals |

| Maintenance | Low maintenance

No cracking or peeling |

May require touch-ups over time

Prone to cracking |

| Quantity | Cost-effective for small to medium quantities | Economical for large quantities

Setup costs for each color |

| Price | Higher cost for small quantities

Lower for larger runs |

Economical for large quantities

Higher for small runs |

The bottom line

And there you have it – the colorful clash between sublimation vs screen printing! Both techniques offer high-quality and eye-catching prints in their own way.

Sublimation fuses ink into fabric for soft, breathable prints with vibrant colors that don’t fade or peel over time. Awesome for athletic gear and performance wear! Screen printing lays ink boldly on the surface for a classic feel and endless creative freedom. Perfect for artistic flair on T-shirts and paper!

For print on demand businesses, sublimation brings efficient digital printing with no minimum orders. Choose screen printing if high volume wholesale deals are your goal!

At Merchize, we offer a diversity of printing methods to deliver stunning, customized merch no matter your needs. Our experienced team helps identify the best approach for your vision and business. You can take a look at our product catalog to decide what strengths matter most for your business. Then rock some dazzling prints and let the design magic happen with Merchize!