With print on demand, sublimation products give you some unique offerings that can leverage your bottom lines. If you want to try out this line of products, go through this list of the best sublimation print on demand companies and their respective pros and cons.

What makes a good sublimation print on demand company?

Before choosing what’s right sublimation print-on-demand company for your business, you must take into consideration some of the following factors:

Number of products

The more products, the better. For sublimation printing, it is easy to create new products as nearly everything is printed, cut, and sewed from scratch, and there is no need for blank products.

That’s why you can find many different types of products made with sublimation printing. Compared to other basic DTG products that are already saturated and incredibly competitive, you should seek out providers that can give you rarer options.

Based on the niche you are targeting, you can also extend your search and find what sublimation print on demand companies can give you potential products for that niche. For example, if you are focusing on niches like sports or outdoor activities, products like baseball jerseys, jersey shorts are some great options to appeal to the customers in your niches.

Level of customization

Whether your designs turn out great and match your initial ideas or not really depends on how much you can customize the products. Ideally, with sublimation print on demand, you can customize all parts of the products.

However, there might be some limitations to what material can be applicable for sublimation printing. For some products that mix materials, it might not convenient to print and sew every part of the products.

So, here’s one sublimation print on demand tips for you: before selecting what products to sell, don’t forget to double-check what parts of the products are customizable. It’s best to find a supplier that allows you to customize products as much as possible.

Product quality

All-over print products are made entirely by the print on demand suppliers. There is no certain blank product brands like Gildan, Bella + Canvas, Hanes, and so on. So the qualities might vary greatly.

It’s better to make sure that the product quality is up to your expectations.

>> Read our blog post to have better understanding of the difference between sublimation vs direct-to-garment printing.

Top sublimation print on demand companies

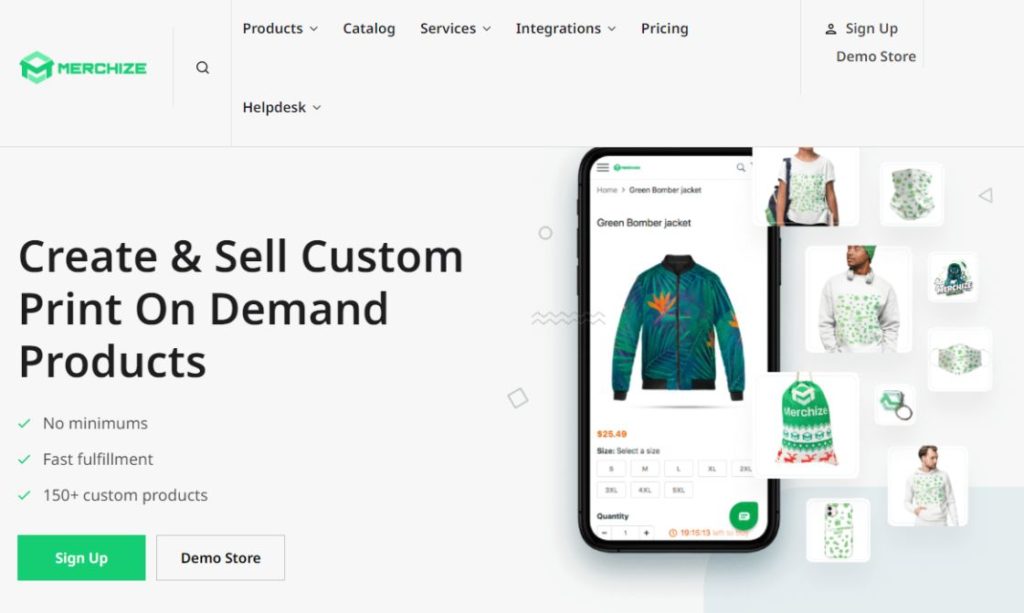

Merchize

Merchize has one of the best sublimation print-on-demand collections. Our all-over print selection covers a wide range of categories, from basic T-shirts, and hoodies to unique items like bomber jackets, baseball jerseys, polo, and Hawaiian shirts. With all various options, you can find opportunities in many different niches.

Why you should choose Merchize’s all-over print products?

Wide variety

At Merchize, we have developed an extensive all-over print product catalog that includes the best sublimation print on demand products for your business. You can easily find the right products for your niche and audience.

Even for one line of products, for example, polo shirts, we have released different types of polo shirts, from long to short sleeve, men’s to women’s.

To push the variety even further, we provide different material options. Take polo shirts, for instance, there are lightweight and midweight versions. Depending on your budget or product requirements, you can pick the right version for your store.

Competitive pricing

Basecost is a critical concern for all-over print products. This type of product usually costs more than regular DTG items due to the higher production costs.

To reduce the traction and make it easy for you to switch from regular products to all-over print, we continuously optimize the production for better base cost and efficiency.

Plus, around the year, we also offer some big discounts to help sellers make the most of their all-over print product lineup.

Branding options

There is more room for you to develop your own special offerings and positions in the market. That’s why it is much easier to build your brand with all-over print products.

In order to help print on demand businesses develop sustainable, strong branding, Merchize provides beneficial and valuable brand options. With Merchize, you can customize your packaging, tags, label, or inserts to match your brand identity and leverage brand impression.

Best for

Regardless of your business size, whether you are just a beginner or an experienced print on demand business with massive orders and specific requirements, Merchize ensures to deliver the best solutions for you. You can get the best prices, all-round products, and attentive support. Especially when it comes to sublimation print on demand, Merchize got you covered with diverse options and great base costs.

Printful

Printful is a well-known print on demand provider that is very popular among print on demand businesses. It is a convenient and beginner-friendly option for people who just start tapping into the print-on-demand market.

While Printful has one of the most extensive DTG products with consistent quality, Printful also caters to the need for all-over print products with some sublimation print-on-demand options.

| Pros | Cons |

| Over 70 all-over print products in 15 categories, with some great accessory products. | High base cost – Prinfity’s products and services require excellent print on demand yet at an expensive price. |

| Advanced built-in tools – for example, easy-to-use mockup generator. | Not many options for the apparel category |

| Various services including versatile branding options |

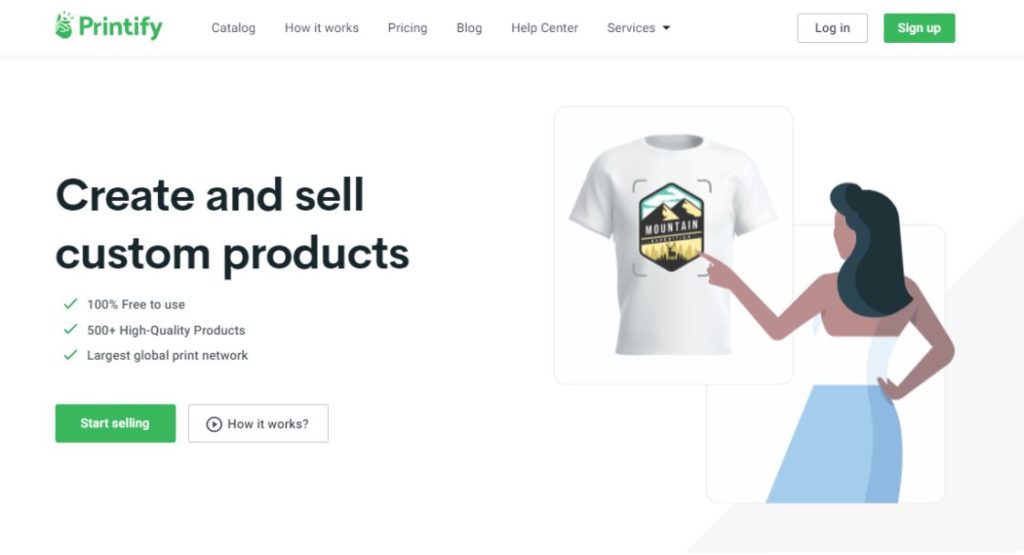

Printify

Printify is a platform that helps print on demand businesses connect with printing providers across the world. Thanks to the large network of providers across the globe, Printify can deliver the flexibility that is needed to make sure your business runs smoothly.

They also have an extensive all-over print product catalog that extends across different categories.

However, most of these all-over print products on Printify are made in China, which will take much longer to deliver to buyers. It should also be noted that these printing providers are just Printity’s partners. The printing and product quality might differ widely from provider to provider. It is harder for Printify to control the quality of each order printed.

| Pros | Cons |

Wide selection of products in different categories. | Inconsistent product quality |

| An extensive network of printing providers across the world ensures a smooth supply chain. | Long shipping time |

Art of Where

ArtOfWhere is a Canadian-based sublimation print-on-demand provider that has been in the biz since 2013. They handle everything from printing, sewing, to quality control in-house, which ensures that their customers receive high-quality products every time.

Located in Canada, ArtofWhere is about to work closely with manufacturers and providers in North America, helping ArtofWhere to deliver quality products with the best materials, from polyester and spandex to other exclusive raw materials.

At ArtofWhere, you can find unique products like capris, kimono robles headbands, and origami bags. This range of products is perfect for artists to release their merch as well as print-on-demand sellers who want to test and try new unique products.

The downside of ArtofWhere is that this provider might require a longer procession time. It might take up to 6 days to print a product, which is slower than most print on demand companies out there.

Also, ArtofWhere has only a smaller collection of all-over print products compared to other major print-on-demand vendors.

| Pros | Cons |

| High-quality materials and strictly controlled in-house manufacturing. | Longer processing time |

| Selection of unique all-over print products. | A limited number of all-over print products. |

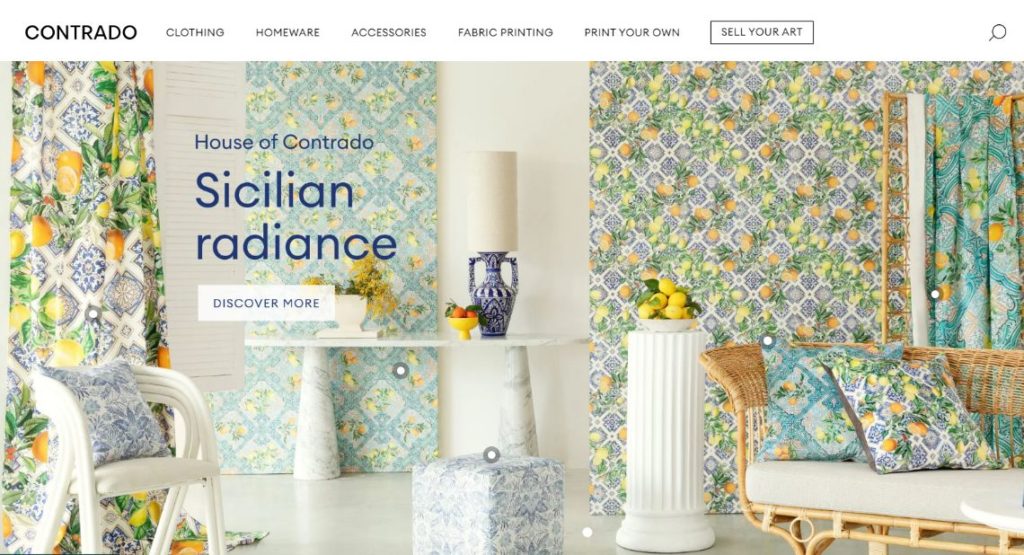

Contrado

Contrado is a worth-considering print-on-demand provider coming from the UK, especially if you are selling for the European market.

The US-based print on demand provider gives you more than 450 products with arrays of all-over print items that include apparel and accessories like wallets, purses, or even fabrics and furniture.

Contrado also ensures an efficient manufacturing process with a short processing time. In just 1-3 days, products are set to be shipped. In addition to all of that, Contrado also provides various branding options for POD businesses.

However, many print on demand sellers are still hesitant to use Contrado’s services due to the premium pricing. It can cost from $32 for a T-shirt and $105 for a hoodie, not including the shipping costs.

While their dropshipping subscription fees are free, the overall cost of their products can be prohibitive for those looking for cheaper options.

| Pros | Cons |

| Extensive catalog of all-over print products | Very expensive. |

| Unmatched quality, suitable for premium brand building | |

| Fast processing time |

Sublimatinator

Subliminator is familiar to people who already made money with all-over print products. They also offer attractive pricing compared to other competitors from the US or EU. However, it should be noted that its products are made in China offering merchants lower costs compared to many of its competitors in Europe and America.

Their product catalog includes various sublimation print on demand options that give you good opportunities to sell.

Yet. the catch here is the lack of quality control and longer shipping time. As the manufacturing facilities are based overseas, it is incredibly difficult to overlook the production process, which leads to inconsistency in terms of quality.

This option is also not for print-on-demand business that wants to develop sustainable business in the long run.

| Pros | Cons |

| Wide variety of sublimation products. | Inconsistent product quality |

| Affordable pricing compared to other EU, and US-based providers. | No branding service |

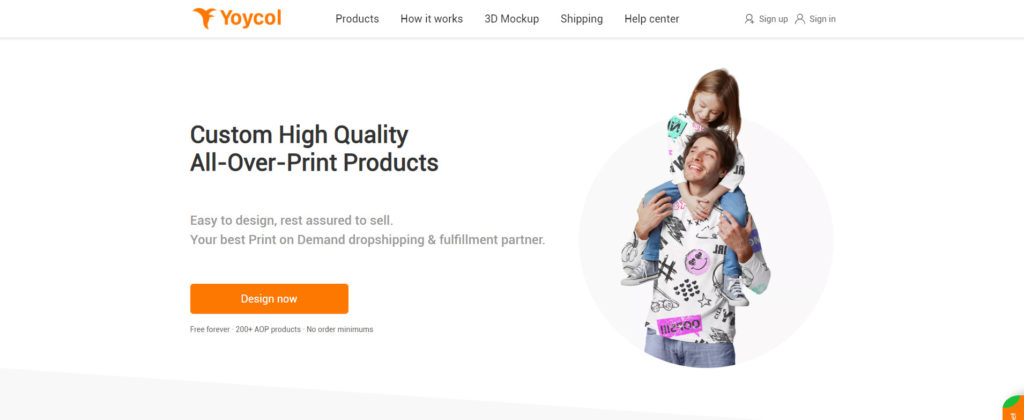

Yoycol

Yoycol is a print-on-demand provider from China – the super nation of manufacturing. The Chinese suppliers have one of the most extensive collections of all-over print products. The price is also very competitive. This is a great option for those who want to test and experience some unique products.

But if you are looking for a reliable supplier with consistent quality, you should consider it carefully. It may take longer to receive products due to shipping times from China, which could be a consideration for businesses that require faster delivery times. Reportedly, there are also some issues with the tracking system, which is a huge concern for POD merchants, especially during the peak season.

| Pros | Cons |

| Large collection of sublimation products | Quality control issues |

| Competitive pricing | Limited branding options |

| Lack of transparency | |

| Language barrier | |

| Longer shipping time |

This New

ThisNew is another sublimation print-on-demand companies from China. Besides providing print on demand products, this company also helps sellers who are doing dropshipping.

Back to its print-on-demand services, ThisNew offers a huge selection of sublimation products. With facilities located in China and North America, this supplier has reliable manufacturing power. However, there are still some serious concerns when it comes to the quality of their products and services.

| Pros | Cons |

| Large collection of products, including all-over print products | Longer shipping time |

| Huge manufacturing capacity | Quality control issues |

With this list of the best sublimation print on demand companies, you can turn your creativity into a successful business or create personalized products that will delight your customers.